The laboratory of energy production and energy saving technologies

1. Technology of restoration of salt ground

By collecting water from 12 lakes, which are situated along a salt drainage system of Turkmen lake “Altyn Asyr” and 16 ponds of our country into a complex “Geliobioplato”, additionally feeding with “Bioadds”solution, concentrated with “Saprophyte” bacteria, activating photosynthesis process under effect of Sunbeam grown up unicellular seaweeds. Further, by adding granules of nature gypsum into structure of unicellular seaweed in the complex “Geliobioplato” and in consequent of recycling received a new “Eco-fertilizer”. Finished “Eco-fertilizer” is added into a structure of soil (into the structure of slight salted soil – 2 ton, medial – 6 ton, heavy – 10 ton) in period of preparing to the conducting washing water of salt ground.

As a result, there is achieved technology of salt reducing, which rise with underground water and maintaining in the productive part of soil minerals and organic fertilizers, which are used to feed the soil. Self-repayment of expenses of the equipment in production T = 6 years.

2. Technology of a feeding agricultural plants through their stalk.

In a consequence of cultivation of monocelled seaweed by means of an additive of a solution of "Bioadds" with “saprophyte” bacteria in structure of thermomineral waters of our country rich on microcells "extract" is received. Having added in structure of received "extract" certain weight of granules extinct to exhaust, it is made “emulsion”. On the basis of use made to exhaust, rich on microcells, calcium and seaweed scobs the technology of a food agricultural plants through their stalk has been developed.

Considering high advantage in all corners of our country, especially in the decision of problems on working out energetically economic, non-polluting technologies by use of the restored energy sources, the considered offer can be used in manufacturing of projects directed a food agricultural plants through their stalk by use “calcinated seaweed emulsion”. Self-repayment of expenses of the equipment in production T = 4 years.

3. Technology of drying of products grown up in agricultural economy

The installation, working by a principle of "Heliodryer-hothouse" during summer-autumn time and by a principle of a hothouse in a winter-spring season is developed, which allows to make a melon candied fruit, raisin, dried medicative herbs and other products by complex processing vegetable and melon products, grapes, fruit and the berry fruits which are grown up on agricultural economy of our country.

Considering high advantage in all corners of our country, especially in solving problems on working out of energetically economic, non-polluting technologies by use of the restored energy sources, the considered offer can be used in manufacturing of projects directed manufacturing of a melon candied fruit, raisin, dried medicative herbs and other products in installation "Heliodryer-hothouse". Self-support of expenses of installation in manufacture Т = 1,6 years.

4. Technology of reception ceramic a covering covered with white glaze and a power saving up brick from local raw materials

The checkered brick covering, being the new building product, prepared of local raw materials, for the purpose of reduction of unpleasant technical sounds outside and losses of heat from walls of the living house is received. This checkered brick will create possibility of continuous economy of energy and isolation of external sounds in the housing house at all times year.

As, the ceramic covering covered with white glaze is received. As a part of glaze non-polluting components are used. The basic part of glaze consists of residual glass. Residual glass is crushed to level of a powder and the consequence of an additive of auxiliary components and careful mixing makes glaze. It is very important to consider such external factors as temperature external and humidity of air at manufacturing of the above-stated material. Self-support of expenses of installation in manufacture Т = 6,2 years.

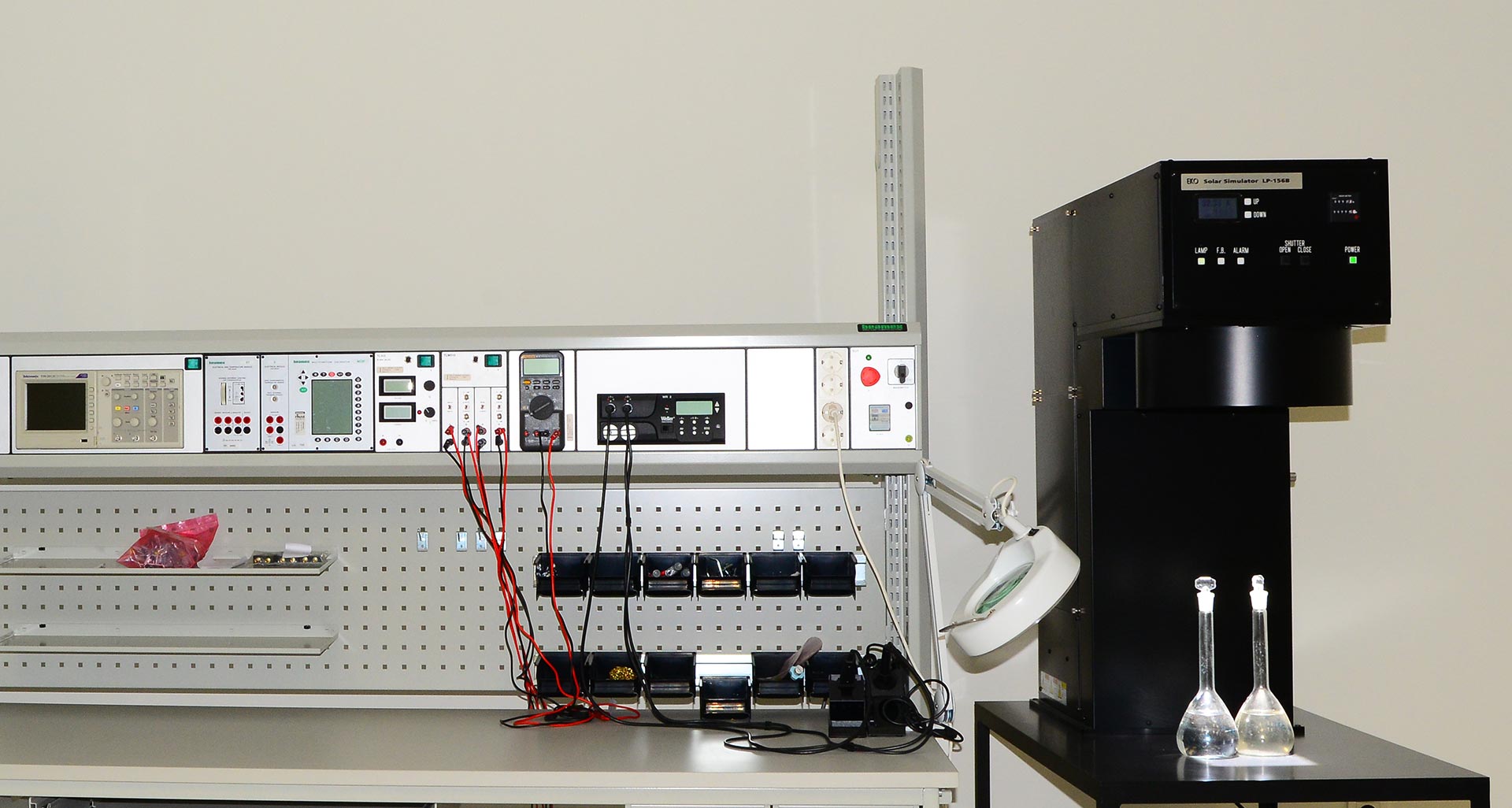

- Inspection and repair (degreasing): electronic sensors, pressure, pressure gauges, vacuum gauges, vacuum gauges, diaphanometers;

- Checking temperature meters and electronic sensors: temperature from -30 to 1800 degrees Celsius;

- Checking and calibration of pressure sensors operating on: air (gas), liquid (water);

- Checking and calibration: thermocouples, resistance thermometers, glass and manometric thermometers, immersion type thermal relay;

- Checking and calibrating electrical, electronic transducers and measuring instruments: voltmeters, ammeters, signal generator, oscilloscope, converters, digital voltage, current, resistance meters, etc.;

- Checking: liquid analyzers;

- Carrying out technological audit: on industrial production equipment;

- Carrying out work on flaw detection: on industrial production equipment (on the ground);